Continuing our policy of innovation and upgrading our machine park, we have equipped ourselves with the latest control tools for managing production processes capable of operating in the field of equipment for dimensional inspection of the part.

The first step was the acquisition of 3D software programs for the development of two- and three-dimensional working drawings in a high-precision environment.

The 3D software system enables us to offer our Customers free of charge assistance in the dimensional definition phase of the tool (broaches, inserts, gauges and control pads) by designing the executive drawing for the Customer’s approval.

The second step was the acquisition of a Profile projector combining optical/video high-resolution measurement technologies guaranteeing a “measurement uncertainty” of 2 um.

Metrology sotware allows image acquisition of the machined tool profile and creation of a report containing dimensional characteristics complete with tolerances and management of dxf files for comparative measurements by overlaying the two profiles.

GAUGES AND CHECK GAUGES G/NG FOR INTERNAL AND EXTERNAL POLYGONAL PROFILES

After many years of experience gained in the broaching/routing tool market, we thought of serving all issues related to control systems for internal/external polygonal profiles according to current national and international standards.

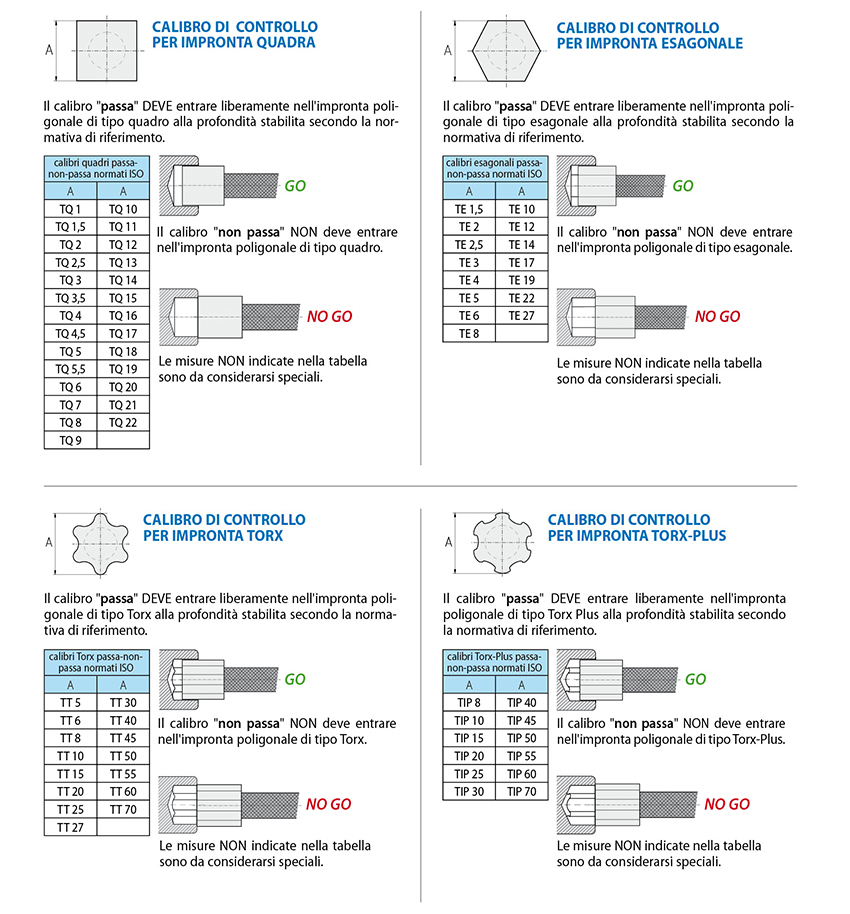

Therefore, we have made a series of G/NG gauges for TORX, hex and square profiles.

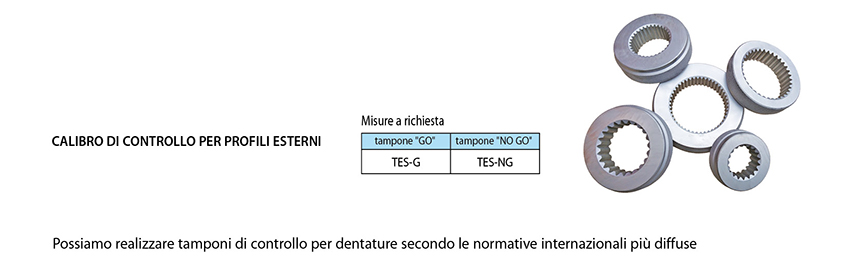

We have also ventured into the field of spline profiles with both G/NG rings to control straight-toothed and evolving spline shafts and G/NG buffers to ensure proper dimensional construction of the internal profile.

Normally for control gauges and plug gauges made according to the most commonly used standards are available from stock. In other cases they are produced in the shapes and dimensional characteristics according to the Client’s requirements.

We can provide calibration certification upon request.

The construction of check plug gauges in TORX profiles for interior (TORX T5 to TORX T60); and exterior (E1 to E16), hexagonal (ES1 to ES28), and square (Q1 to Q25) plug gauges takes place within the tolerances of ISO-DIN standards.

The pads: hexagonal, square and the other polygons may have special dimensions and tolerances, such products are outside the international standards, and are therefore defined by customers.

Regarding ring plug gauges for external profiles and gauges for internal profiles, with respect to the verification of grooved profiles or serrations, they are constructed in accordance with the measurements required by customers or international standards.

Such rings and gauges, for the most part, are performed individually to verify correct profile executions.

CHECK PAD FOR POLYGONAL PROFILES

CHECK PAD FOR KEYWAY SLOTS

CHECK PAD FOR TOOTHED PROFILES